It converts aligned point clouds into highly accurate polygonal models using PolyWorks' unique tolerance-based adaptive meshing technology. The offered Poly Works Modeler generates manufacturable class A polygonal models.

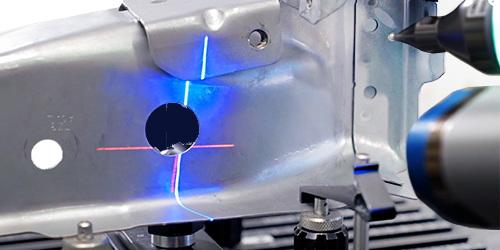

Monitor the production cycle by automatically measuring the wear of tools and quickly detecting any abrupt degradation in product quality.Approve your manufacturing process by fully inspecting your first-assembled products.Use high-density point clouds and contact-probe datasets of digitized prototype parts & assemblies to quickly identify deformations and to fix problems in the earlier stage of the manufacturing process.The 3D-digitizing of arbitrary object, such as work pieces, models and moulds, can be resized, without actual contact with the object, for usage in several domains. The application covers the results of the information, statistically. The data and images, generated automatically, are analyzed and evaluated within a fraction of a second, utilizing digital image processing. This maximizes the precision of this Poly Works Inspector. The measurement process used by this application is based on the principle of optical triangulation.

0 kommentar(er)

0 kommentar(er)